s-drill

The Kverneland s-drill is the right choice for medium-sized farms.

Heavy-duty cultivator-mounted seed drill, perfect for medium-sized farms

Highlights

Compact design with close centre of gravity Precise seed placement by CX-II coulter Even depth control by coulter pressure adjustment Large hopper for reduced set-up timesDescription

The Kverneland s-drill is a heavy-duty cultivator-mounted pneumatic seed drill and is the perfect solution for medium-sized farms looking for an efficient and sturdy seed drill. The s-drill is offered in working widths of 3.0, 3.5 and 4.0 meters and a hopper capacity of 1,050 litres. Thanks to the universal coupling triangle, the heavy-duty s-drill can be mounted on existing Kverneland power harrows and other soil preparation tools.

The compact design of the cultivator-mounted seed drill with a close centre of gravity reduces the power requirement of the machine. To fully protect the seeds and distribution head against dust and humidity, the heavy-duty hopper has a robust steel cover which can be opened completely to allow for hopper filling with a front loader, big bags or filling auger.

Highlights

- Compact design with close centre of gravity for reduced power requirement

- Precise seed placement by CX-II coulter

- Even depth control by coulter pressure adjustment, either mechanical or by hydraulic

- Large hopper of 1,050 litres for reduced set-up times and increased performance

- Easy access via wide loading steps

- Robust cover to be opened completely

Features

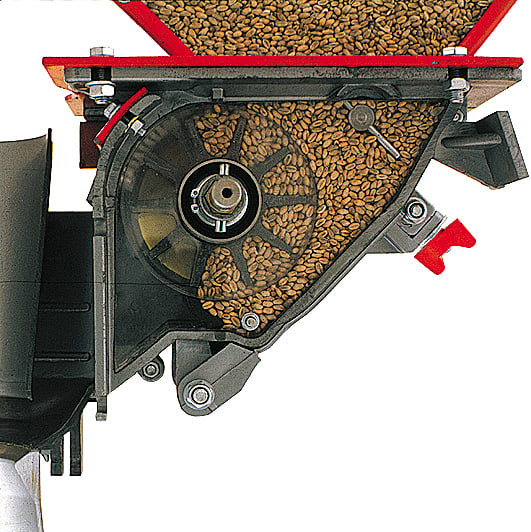

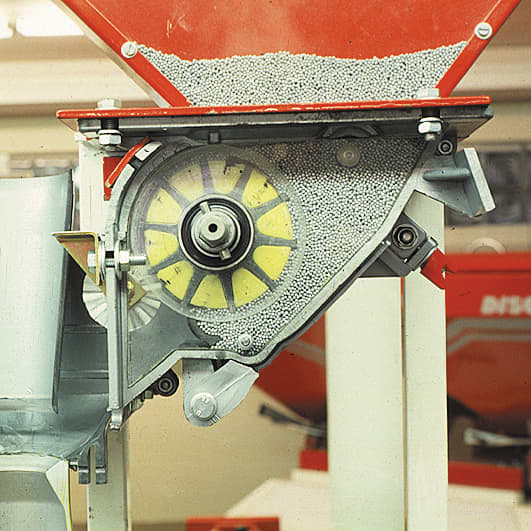

- The central metering device accurately metres any desired volume of seed from 2kg per hectare to 380kg per hectare

- For the sowing of fine seeds, e.g. rape or grass, the metering device can be infinitely adjusted to fine seed/micro-metering by means of a spindle, without any need for tools.

- The metering system is mechanically driven via the spiked landwheel running in the tilled soil.

- The metering device is centrally positioned and easily accessible under the hopper.

Apart from the well-known tramline control FGS and the Signus, the pneumatic seed drills can be equipped with the Tellus GO+ and the IsoMatch Tellus PRO.

Tellus GO+

Tellus GO+ is especially developed for controlling the machine in a simple way. Easy set up the machine with the soft keys via the 7-inch touch screen. And, optimal control while driving, just use the hard keys and rotary switch.

IsoMatch Tellus PRO – the next generation universal ISOBUS Terminal

- Two ISOBUS interfaces in one terminal

- Multifunctional ergonomic design

- ISOBUS Shortcut Button (ICB)

With this new terminal you can work all the way as a PRO. The maximum working range for the task controller IsoMatch GEOCONTROL is increased from 2 km to maximum 10 km from the starting point. Thus even extremely big fields are handled in a full professional way. The new high brightness screen increases operator comfort. Visibility is increased during the day and dimmed to just a glowing display in dark conditions.

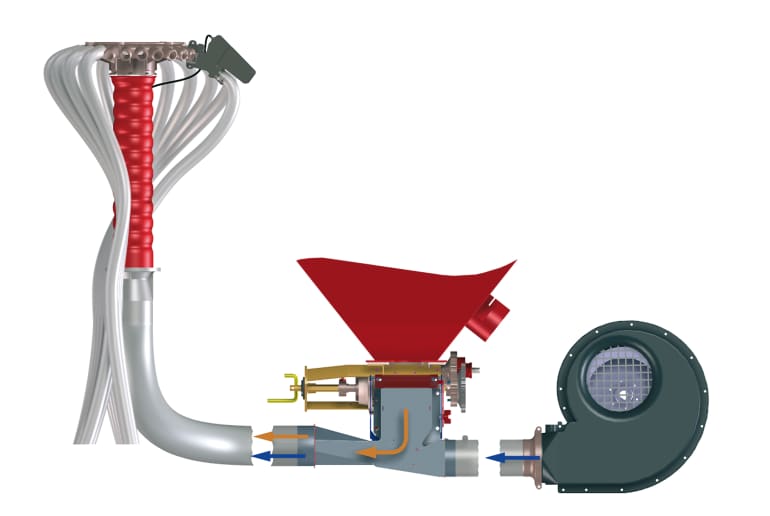

- The central, totally enclosed cell wheel of the metering device accurately measures the required volume of seed and discharges it into the venturi cone where it is mixed with the air stream and then conveyed through the diffuser tube and the seed delivery hoses to the coulters.

- The distribution head is mounted in a protected position inside the seed hopper.

- The CX-II disc coulter from Kverneland not only guarantees smoother running but also exact seed placement.

- The flatter cutting angle of only 5.4° of the steel disc requires less pulling power to reach a constant seeding depth of up to 6cm.

- Due to the combination of the steel disc with a diameter of 325mm and the flexible plastic disc, there is no need for independent scrapers, saving the cost for expensive wearing parts. In addition the coulter is completely maintenance-free!

- Up to 50kg coulter pressure can be achieved by a pre-loaded spring. Safe operation is ensured when working with high working speeds and high quantities of plant residues on the soil surface.

- An inter-row coulter spacing of 445mm for maximum clearance and the following press wheel (standard equipment) ensure an optimum seed/soil contact in all conditions.

- The press wheels can be set in fixed, floating of lifted position in order to be able to adapt quickly to changing weather, soil or working conditions.

- The CX-II coulter is also available as light edition without press wheel which reduces the weight and length of the coulterbar. This will allow to operate the seeding combination also with lower lifting capacity of the tractor.

Precision Farming

When deciding what equipment to purchase, it is not always easy to find the optimal solution in the broad market offering of today. Technology is developing fast and tractors and implements are more and more equipped with high tech electronics. We understand this complexity and are committed to provide you with easy farming solutions. Therefore these cost-efficient ISOBUS Universal Terminals, IsoMatch Tellus PRO and IsoMatch Tellus GO+ are made for easy machine control and efficient farming.

With its advanced hardware and software features, the IsoMatch Tellus PRO provides the optimal precision farming solution for an all-in-one control system inside your tractor cab.

IsoMatch Tellus PRO is the centre for connecting all ISOBUS machines and a platform for running precision farming applications. It offers everything a farmer needs to get the maximum out of his machines and crops, as well as cost savings in fertiliser, chemicals and seeds by using automatic section control and variable rate control. With the unique dual screen functionality it gives the farmer the opportunity to view and control two machines and processes simultaneously.

Work easy. Be in control.

IsoMatch Tellus GO+ is especially developed for controlling the machine in a simple way. The farmer is in full control of the machine in exactly the way he wants. Easy set up the machine with the soft keys via the 7-inch touch screen. And, optimal control while driving, just use the hard keys and rotary switch. Controlling the implement has never been so easy.

This can be you your first step into Precision Farming

IsoMatch Tellus GO+ makes it easy to control any ISOBUS machine from your tractor cab. IsoMatch GEOCONTROL enables you to achieve higher yields, lower costs and do your work with less hassle. This licence key is divided in two parts, Section Control and Variable Rate Control, which are available from the IsoMatch Shop. Now you can buy the specific functionality that you need.

The essential accessory for IsoMatch GEOCONTROL.

The IsoMatch Global 3 is the GPS antenna, with DGPS accuracy, in the IsoMatch product range. It enables satellite navigation for site-specific section control, variable rate application, manual guidance and field registration.

SMART

Allows manual guidance, automatic section control and variable rate in combination with IsoMatch GEOCONTROL

EFFICIENT

DGPS accuracy without additional subscription fees

EASY

Easy to fit with mounting brackets included

The IsoMatch Eye is the camera option in the IsoMatch product range.

IsoMatch Eye is a camera that has been developed for use with our sophisticated IsoMatch Tellus GO+ and IsoMatch Tellus PRO dual screen terminal. The IsoMatch Eye is switchable from rear view to standard view.

It gives you full control and overview of entire machine operation during day and night, because of its night vision by integrated LED’s. This increases the safety e.g. when reversing the machine or manoeuvring around obstructions.

SMART

Changeable from rear view to standard view

EFFICIENT

Full control and overview of entire machine operation

EASY

Night vision by integrated LED’s

IsoMatch MultiEye is an accessory for connecting multiple cameras to the IsoMatch Universal Terminal.

With the IsoMatch MultiEye you can connect multiple cameras to the IsoMatch Tellus PRO or IsoMatch Tellus GO+ Terminal. You can easily switch between the cameras without the need for an additional screen in you tractor cabin. It gives you full control and overview of the entire machine operation during day and night, because of its night vision by integrated LED’s. This increases the safety when reversing the machine or manoeuvring around obstructions.

SMART

You can connect up to four IsoMatch Eye cameras and easily switch between the cameras with the remote control box which is standard included.

EFFICIENT

Full control and overview of entire machine operation from every side you want.

EASY

Night vision by integrated LED’s which increases the safety when reversing the machine or manoeuvring around obstructions.

Connect to a local wireless network on your IsoMatch Tellus.

IsoMatch Wireless (USB-stick) is complementary to the IsoMatch Tellus and makes it easy to connect to a local wireless network, such as your phone’s hot-spot, home network etc.

No additional costs of an internet service provider. When connected via the IsoMatch Wireless you can browse the internet, view the weather, Gmail, Google, etc.

With manual guidance you are perfectly on track.

The IsoMatch InLine is a light bar which allows easy manual guidance. It is the perfect assistant to get you as close as possible to your desired A-B line. Mounted in the line of sight, you can easily see the distance from the A-B line and to which direction you should steer for the ideal position. The display of the IsoMatch InLine also displays the status of the machine sections, which adds more comfort of use. The LEDs can be dimmed for night operation.

SMART

Distance to A-B line with LED indication and a numeric display

EFFICIENT

Manual guidance in combination with IsoMatch GEOCONTROL

EASY

Displays status of machine sections

Made for smart, efficient and easy farming

IsoMatch GEOCONTROL is an advanced software application within the IsoMatch Tellus PRO and IsoMatch Tellus GO+ that helps you to control all ISOBUS compatible Kverneland Group machines such as sprayers, spreaders and seeders! Combined with a GPS receiver it fulfils the future needs in terms of easy, smart and efficient farming!

Technical specifications

Technical specifications

Download brochure| Model | s-drill | s-drill | s-drill | |

|---|---|---|---|---|

| Maschine type | cultivator mounted | cultivator mounted | cultivator mounted | |

| Working width (m) | 3.0 | 3.5 | 4.0 | |

| Transport width (m) | 3.0 | 3.5 | 4.0 | |

| Hopper capacity (l) | 1,050 | 1,050 | 1,050 | |

| Hopper extensions (l) | Standard | Standard | Standard | |

| Quick emptying chute | Standard | Standard | Standard | |

| Low level sensor | Standard | Standard | Standard | |

| Drive 1000 rpm | Standard | Standard | Standard | |

| Drive 540 rpm | Option | Option | Option | |

| Hydraulic fan drive | Option | Option | Option | |

| Mechanic metering device (No.) | Standard (1) | Standard (1) | Standard (1) | |

| Micro metering | Standard | Standard | Standard | |

| FGS - Tramline system | Option | Option | Option | |

| Signus - Tramline system | Option | Option | Option | |

| Metering device control | Option | Option | Option | |

| Seed rate adjustment | Option | Option | Option | |

| Seed quantity (min. - max.) | 2 - 380kg/ha | 2 - 380kg/ha | 2 - 380kg/ha | |

| Shut-off valves for tramlines | Option | Option | Option | |

| Mechanic half-width shut-off | Option | Option | Option | |

| Pre-emergence marker | Option | Option | Option | |

| Vertical hydr. folding track marker with notched disc | Option | Option | Option | |

| Vertical hydr. folding track marker with notched disc | Option | Option | Option | |

| No. of coulters 12.5cm distance (standard) | 24 | 28 | 32 | |

| CX-II coulter incl. press wheel | Standard | Standard | Standard | |

| CX-II coulter disc Ø (mm) | 325 | 325 | 325 | |

| Press wheel Ø (mm) | 250 x 42 | 250 x 42 | 250 x 42 | |

| Coulter pressure CX-II disc coulter (kg) | 5 - 35 | 5 - 35 | 5 - 35 | |

| Mechanic coulter pressure adjustment by crank | Standard | Standard | Standard | |

| Hydraulic coulter pressure adjustment | Option | Option | Option | |

| S-tine harrow (10mm) | Option | Option | Option | |

| Calibration set | Option | Option | Option | |

| Loading step / Platform | Option | Option | Option | |

| Lighting equipment | Option | Option | Option | |

| Oil charge hydr. fan (l/min) | 40 | 40 | 40 | |

| Min. power requirement (HP/kW) | 90/66 | 90/66 | 90/66 | |

| Weight *(kg) with coulters | 618-1,100 | 618-1,100 | 618-1,100 |

* Weight without power harrow

Technical specifications

Technical specifications

Download brochureWorking Width |

Hopper Capacity |

Weight |

|

s-drill |

3.0/3.5/4.0 |

1050 |

618 - 732 |

* Weight without power harrow